|

Filter Bag Production Line

Auto Filter Tube Production Line

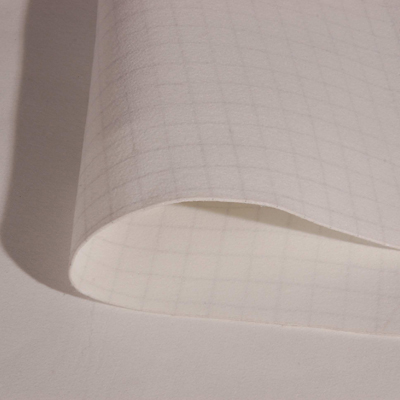

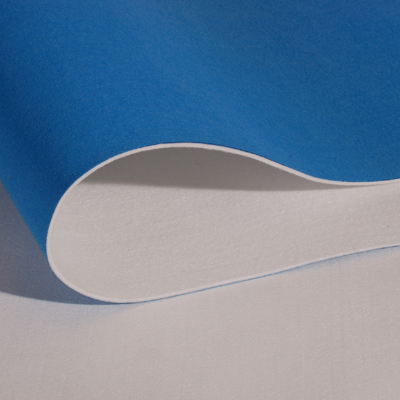

Detail:Application: this machine can sewing the rolls of fabric into tube automatic in need. And sewing speed can achieve 10-12meters/min, 2000 – 3000meters per day. This machine can sewing all kinds of filter fabrics, such as woven fiberglass cloth, FMS felt, Polyester felt, PP felt, Nomex, PTFE felts, PPS and so on. Specification:

The complete line is 16 meters long, the tube table long 9.5 meters, can change according to customer’s need, height 2.5meters, width 1.8meters. Can be divided into five parts

1) Feeding part: length 1.4meters, height 1.1meters, width 1.2meters Max width of fabric roll: 1.1M 2) Auto sewing part: height 1.8meters (including thread coil), height 0.6meter, length 1meter a. Sewing head (Juki-1261), arm add 750px, others are Juki self parts b. Tube holder arm: 12-750px (can make according to customer’s needs) c. Sewing speed: 7-10meters/min (frequency control, speed can be adjusted) 3) Tube storage part: height 2.5meters, width 0.7meter, length 1.8meters Storage tube length: more than 8meters 4) Tube cutting part: height 1.2meters, length 9.5meters, width 1.2meters The length of tube: 9.5meters (can make much longer according to customer’s request) Selected length accuracy: less than 2mm 5) Operation panel: height 0.9meter, width 0.6meter, length 0.4meter Function: manual & automatic

Function of different parts:

1) Synchronous discharge part: adop diameter on 100mm rubber rollers, cylinder word with motor to achieve synchronous discharge 2) Auto sewing parts: Juki-126 mode three needle sewing head, work with pre-shape equipment to achieve auto folding effect 3) Tube storage part: upper & down limited switches to insure leading equipment in sewing part to feeding material on time. 4) Fixed length cutting part: 3.5kw large motor transfer belt to transit filter tube, double imported electric reducer, fix-length, cylinder and laser cutting knife. 5) Operation panel: PLC is the complete machine line control center, use frequency converter, electric relay, screen & control keys to work together, make whole line can running smoothly. More Products

|